"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

07/05/2016 at 11:55 • Filed to: Project Hoondy, Adam's Garage, Clutch, ACT, Flywheel, Tuning

2

2

2

2

"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

07/05/2016 at 11:55 • Filed to: Project Hoondy, Adam's Garage, Clutch, ACT, Flywheel, Tuning |  2 2

|  2 2 |

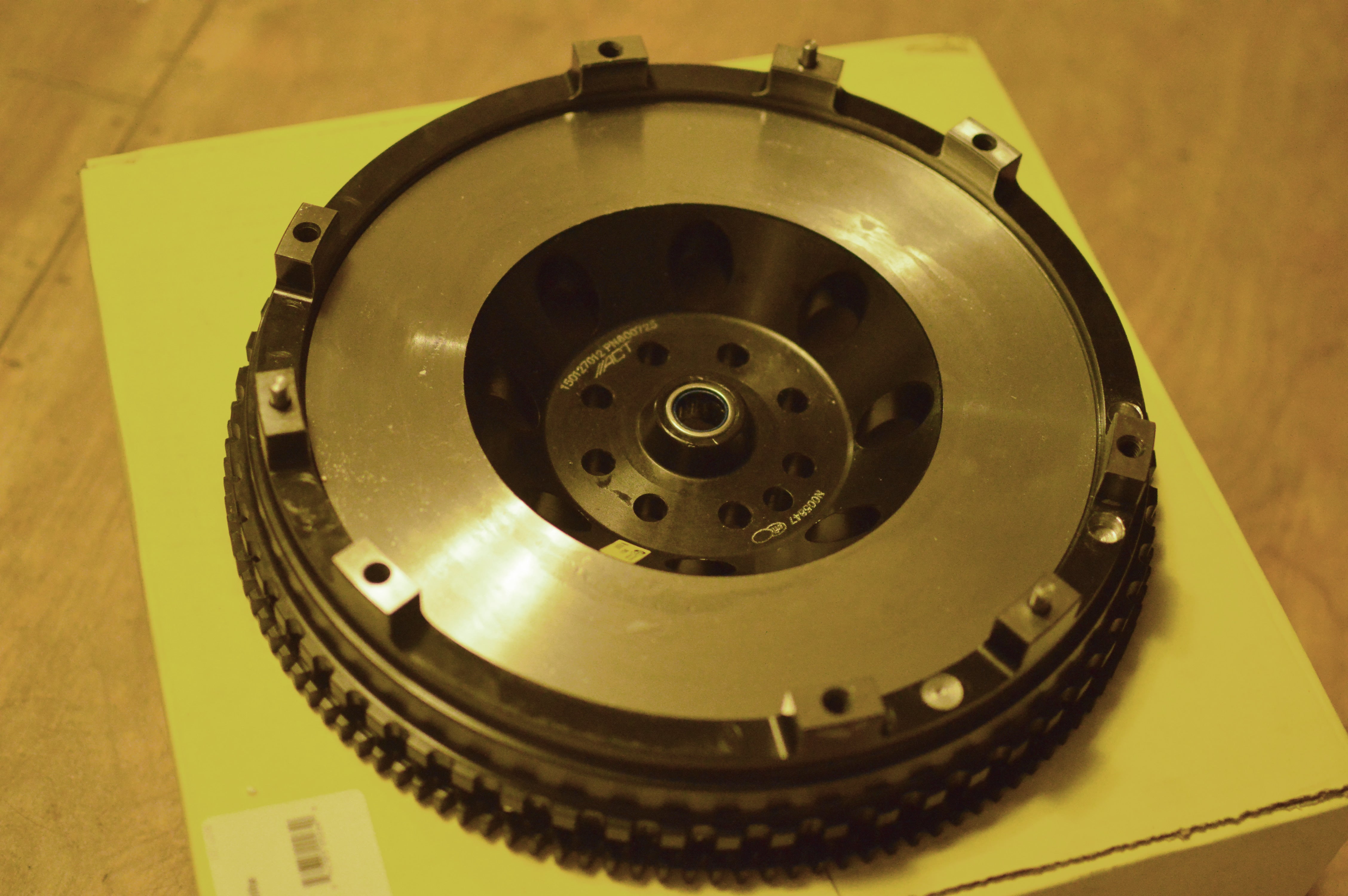

Look at this flywheel. Look at it! 26.5 pounds of USA-made Chromoly magnificence. It was the nicest piece of steel we’d ever owned, and it layed atop a metaphorical heap of goodies that we stood poised to slather

all over

our beloved Project Hoondy. Every component we’d purchased was lighter, stronger, and/or more skookum than the part it would replace. Surely, with nearly two grand’s worth of after-market goodness on hand, our car would be nothing but improved; right?

Due to a failed clutch slave cylinder, we were set to yank the transmission out of our 2010 Hyundai Genesis Coupe. Given all the work involved, and our distaste for the OEM dual mass flywheel, we’d decided to take the opportunity to upgrade our clutch assembly. A lot of thought went into our parts selection, as detailed in a

!!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

In summary, we’d settled on ACT’s then brand-new XACT series single-piece flywheel with matching HD pressure plate and organic/metallic sprung hub friction disk. We threw in some other small parts including a one-piece short shifter, urethane shifter bushings, and a Teflon slave cylinder hose.

We also decided to tweak our choice in transmission fluid at the time. Early in our ownership of the car, we drained the OEM trans fluid (which was disgusting) and swapped it out for Redline MT-85 as per conventional wisdom. MT-85 was a good match for the factory spec, and the higher-quality, ester-based fluid was an obvious improvement. Sadly, it wasn’t perfect, but we had an idea as to how we could fix that.

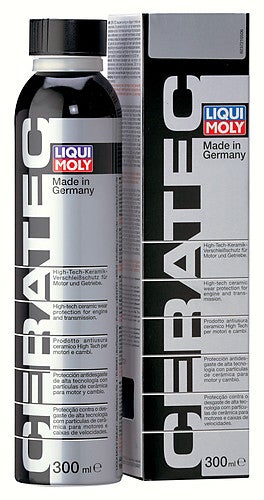

©Liqui Moly

Liqui Moly’s Ceratec was one of the earlier nano-particle lubricant additives to become available to regular consumers. Its ceramic particles form a lattice structure like graphite does, filling gaps and cushioning impacts between metal-on-metal wear surfaces. Liqui Moly recommends running this additive at a rate of %6 total oil volume. That would be 3.8 ounces in our 64 ounce transmission oil sump, but we stayed conservative and used only 2 ounces (60 mL) of Ceratec.

In our experience, nano-particle additives like Ceratec effectively ‘thin’ the oil they are added to. With this in mind, we added the Ceratec to our transmission along with one quart of Redline MT-85 and one quart Redline MT-90. This gave us a light bump in oil viscosity which wound up being perfect.

Performing a full-on clutch replacement is above our pay-grade, so we hired the good people at !!!error: Indecipherable SUB-paragraph formatting!!! to do our dirty work for us. Adam has always given us great service, and is a strong member of the Independent Auto Mechanic Mythos; something we’ve spilled digital ink over !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

What followed was a blur of UPS deliveries and inconvenient car-sharing that can only be accurately conferred in one way:

Queue the montage!

We’re gonna need a montage, montaaage! Ooh it takes a montage, montaaage!

The build went smoothly, though when the old parts came out we found that we weren’t replacing our clutch assembly as frivolously as we had thought.

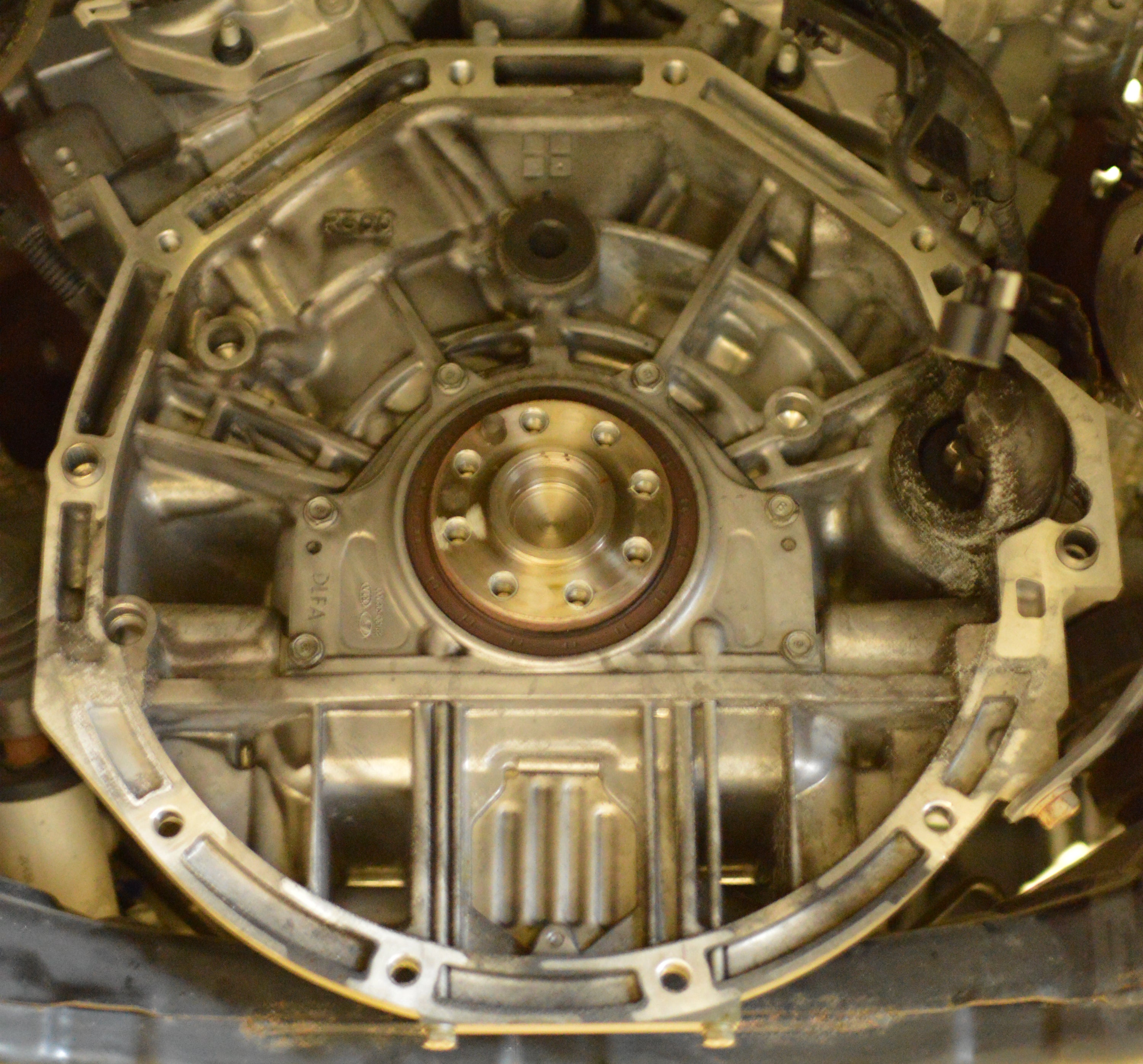

Our OEM dual mass flywheel was completely hashed.

Dry, pulverized rubber fell out of it upon removal, and the two main disks faintly clinked and clanked against eachother as nearly all damping action had disappeared:

Had our slave cylinder not bit the dust, we’d have been yanking our trans out to replace this garbage soon anyway.

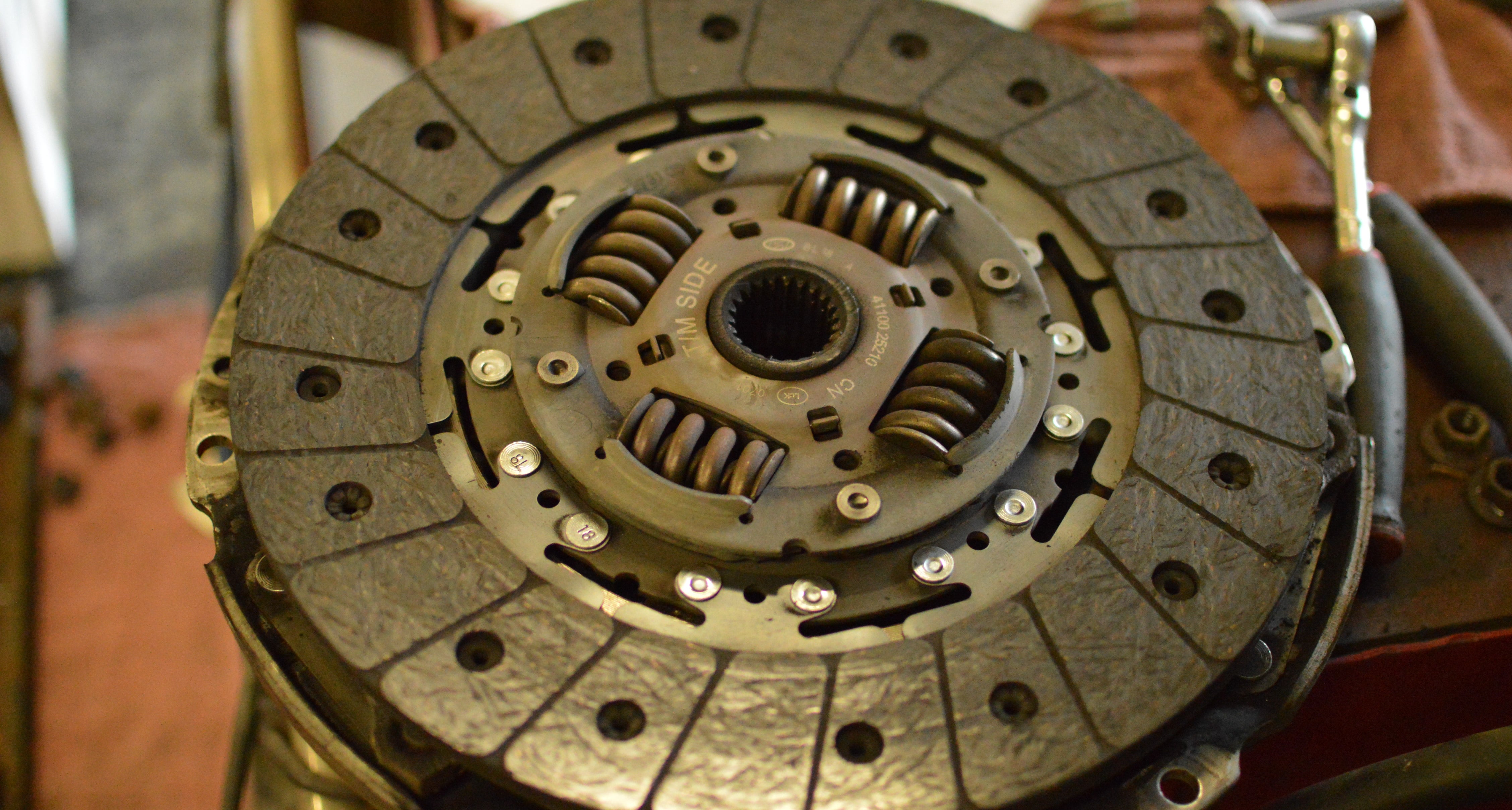

Our OEM friction disk, on the other hand, had fared well. There was plenty of meat left on it with absolutely no sign of glazing. Like the ACT unit that would replace it, this disk was an organic/metallic type with a surprisingly beefy sprung hub. We found it, and the corresponding pressure plate, to be rather impressive for OEM parts:

These components bore a strong resemblance to quality hardware that we’ve seen made by SACHS Clutch. This all fits right in with the theme of the Genesis Coupe being a Korean interpretation of an old-school German sports car. The more we’ve modified Project Hoondy, the more we’ve come to view it that way.

As we had previously suspected, our used OEM pressure plate and friction disk could have bolted up to the ACT flywheel and worked just fine. We’re sure this combo would have given us at least another 40K to 50K miles of trouble-free service. That said, we were happy with our choice to throw all the new ACT hardware in at once. Very happy. Maybe a little too happy:

“k-thack!”

Our new short shifter snapped hard against the freshly installed urethane bushings. It felt like the shift forks were just slicing right through the synchros. Feedback from the synchros could no longer be felt through the shifter at all during fast shifts, which was all the more impressive considering we’d switched from a dampened multi-piece shifter:

To a stiffer, shorter, one-piece model:

We think much of this vast improvement in shift feel can be credited to our new transmission oil mixture. When we talked to Adam about it, he told us that none of our mechanical mods should have resulted in such improvements. Much the opposite in fact, our nasty little short-shifter would only amplify any vibration coming through the selector forks.

Whatever the reason, we could now upshift as fast and aggressively as we wanted through every gearchange. That is, except for the first-to-second swap; which could still be troublesome during our most aggressive launches. Downshifts were even better though. Quick, smooth, and seamless; we were finally in love with heel-and-toe in the Hoondy. The rev characteristics of the engine in general were completely transformed.

We couldn’t be happier with our new clutch build...

Or, that’s what we would have said if it hadn’t been for this shit:

The dreaded shifter rattle! Keen listeners will have already heard it in the first video. Every time we stepped on the loud pedal, our shifter would start growling like an angry chipmunk. Its nasty, piercing rattle took a lot of the fun out of romping on the gas and listening to that big V6 gulp down air.

It turned out that our impulse-buy one-piece short-shifter had been cheap for a reason. We managed to reduce its horribleness with a lovely resin shift knob, but the sound was still pretty awful. We learned to live with it, but vowed to find a solution post-haste.

Also, we decided we should come up with a good excuse to take our car back to Adam’s. Fixing our lame shifter wasn’t enough reason, we had to come up with something bigger to go along with it. Better; way better. The best thing; or at least what we later decided had to be the single best mod we would ever bestow upon our Genesis Coupe.

What could it be!? Tune in !!!error: Indecipherable SUB-paragraph formatting!!! for the pant-soilingly wicked answer here on !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

CalzoneGolem

> Zachary Oberle

CalzoneGolem

> Zachary Oberle

07/05/2016 at 12:06 |

|

Skookum as frig!

Zachary Oberle

> CalzoneGolem

Zachary Oberle

> CalzoneGolem

07/05/2016 at 13:12 |

|

Project Hoondy is gradually becoming a full-on skookum choocher! It will really have earned that title after our next major modification is installed. Stay tuned!